How to operate shearing machine?How does shearing machine work?

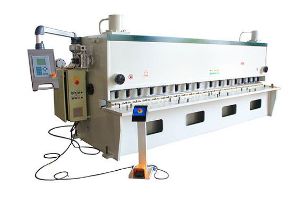

Release Time : 2020-10-26 View Count : 次Shearing machines are widely used in aviation, light industry, metallurgy, chemical industry, construction, shipbuilding, automobiles, electric power, electrical appliances, decoration and other industries to provide the required special machinery and complete sets of equipment. So, how should the shearing machine be used safely? What is the correct operation procedure of the shearing machine? Dalian Mingcheng Electromechanical will take you to find out.

Safety operating rules for shears:

1. Before operation, wear tight-fitting protective clothing, fasten the cuffs, and do not open the hem of the jacket. Do not wear, take off your clothes or wrap your clothes around the machine to avoid distortion of the machine. Safety helmets must be worn, braids should be worn inside the hat, no skirts or slippers.

2. The operator of the shearing machine must be familiar with the main structure, performance and use of the shearing machine.

3. The shearing machine is suitable for cutting various steel plates, copper plates, aluminum plates and non-metallic material plates whose material thickness is the rated value of the machine tool, and must be free of hard marks, welding slag, slag inclusion, and weld thickness.

Shearing machine operation steps

Start the machine for several idling cycles, and try to cut paper of different thicknesses (from thin to thick) while ensuring that there is no abnormality;

Turn on the pressure gauge switch during cutting and observe the oil pressure value. If there is an abnormality, the overflow valve can be adjusted to meet the specified requirements;

Adjust the blade gap to a suitable position according to the plate thickness;

Transport the board to the workbench and place it;

Adjust the rear baffle to a suitable position according to the size of the cutting board;

Push the steel plate slightly to make the edge contact with the baffle plate, and adjust the cutting size;

Step on the foot switch to cut the steel plate;

Repeat ⑷~⑹ to cut a plate;

After cutting one piece/sheet of steel plate, replace it with another piece, and then repeat the process ⑷~⑻;

After the work is over, please turn off the power and perform routine maintenance on the equipment.

Daily maintenance of shears and machine maintenance

If abnormal operation of the machine is found during use, immediately cut off the power supply and shut down for inspection.

When adjusting the machine tool, the power must be cut off. Please pay attention to the safety of your hands when moving the workpiece. All parts of the shearing machine should be lubricated regularly. Operators should refill lubricating oil once per shift, and mechanics should refill lubricating oil every six months.

Check the blade gap frequently, and adjust the gap in time according to the thickness of different materials;

The blade must be sharp, and the cutting surface must be free from weld marks, gas cutting seams and protruding burrs.

When adjusting the machine, it must be stopped to avoid personal injury. Machine accident

During operation, if you find abnormal sound or the fuel tank is overheated, please stop the inspection immediately. The maximum temperature of the fuel tank is ≤60°C