Shearing machine operating procedure-Analysis of shearing machine structure and working principle

Hydraulic CNC shearing machine usually use general-purpose or special-purpose computers to achieve digital program control. The program usually controls mechanical quantities, such as position, angle, speed, and switching quantities related to the direction of mechanical energy flow. The scope of application of hydraulic CNC shears is very wide, ranging from non-ferrous metals, sheet metal, automobiles, ships, electrical appliances, decoration, elevator cabinet doors, to aerospace.

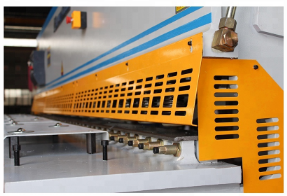

Although the structure of the Hydraulic CNC shearing machine is not complicated, it can be divided into three parts. The front part is hydraulic and spherical parts, which can be lifted and rotated. The middle part is the electric drive roller part. The back part is the support roller. So how do these parts work?

The front part of the hydraulic CNC shearing machine feed configuration mainly includes lower movable and adjustable casters, foot lifts, and middle tail flange hydraulic cylinders. Determine the size of the seat tube according to the actual height of the operating table of the shearing machine. The upper part is circular. The disc is equipped with bearings and universal balls to make the shear steel plate move forward and flexibly rotate during the shearing process, and then equipped with a hydraulic pump and a control box.

When the middle part of the feed mechanism of the hydraulic CNC shearing machine is operating, first determine the transmission speed of the steel plate, and then select the reducer suitable for the conversion, and the pitch diameter ratio of the driving sprocket and the driven sprocket. Note: The transmission speed is too fast to be used correctly, and too slow will affect the production schedule.

In addition, the outer edge of the drive sprocket fed by the Hydraulic CNC shearing machine should not be higher than the roller, and a protective plate is placed in the drive chain, which is the basis for ensuring safe and stable operation. Usually relatively simple, just need to set a few rollers on the top of the frame.

This is to assist the feed structure of the shearing machine, which is usually only used when cutting expansion boards, and can usually be arranged on one side to save space. Although it is very simple, it is required that the top of the bearing housing that is too thin does not exceed the roller for easy operation.

Dalian Mingcheng Electromechanical Equipment Co., Ltd. was established in 2012. It is an enterprise specializing in the development and sales of CNC machine tools and automatic welding equipment. Our main products are plate shears, bending machines, plate bending machines, combined punching and shearing machines, presses, hydraulic presses, laser cutting machines, capping machines, welding equipment, polishing equipment and so on. Precautions for gauge accuracy after adjustment of QC12Y hydraulic pendulum shearing machine.

whatsapp/phone: 0086-13322202758

Choose Mingcheng, which means choosing a good hydraulic machine, door hydraulic machine, large head hydraulic machine, multiple models can be selected

At present, the portable plasma cutting machine is active, with affordable price, fast delivery speed, high cost performance, and a variety of colors and styles to choose from. If you are interested, please consult us directly.