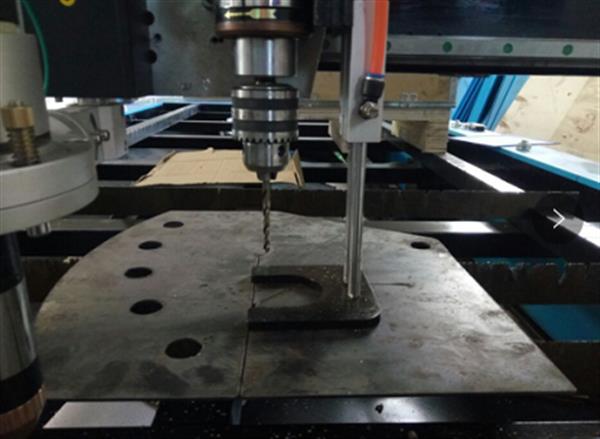

Desk Type Plasma CNC Drilling And Cutting All-in-one Machine

Desk type plasma cnc drilling and cutting all-in-one machine is a high efficiency, precision plasma cutting machine, the use of a one-piece structure to make easy installation, rapid, small inertia, stable operation.

Especially used for cutting medium and thin plate, the machine can be designed as a smoking table according to the user's requirements to meet the environmental requirements.

Desk type plasma cnc drilling and cutting all-in-one machine is designed for cutting all kinds of sheet metal parts in the company's comprehensive consumer market. The machine has fast cutting speed, good surface cutting quality, and can be equipped with suction smoke treatment device.

The cutting speed is up to 10000mm/min.

Product details display

Desk type plasma cnc drilling and cutting all-in-one machine characteristics

1. Longitudinal use of bilateral synchronous drive system, longitudinal use of linear guide, so that the transmission is more stable, higher operation accuracy.

2. The beam is designed with light structure. The structure has good rigidity, light dead weight and small operating inertia.

3. The whole machine structure is tight with its own smoke treatment device.

4. Suitable for all kinds of sheet metal, complex graphics proofing, as well as mass production, save the complex punch mold, save the proofing time, reduce the cost.

5. Fast running speed, ** cutting speed can reach 10 meters/minute, suitable for batch processing, and laser processing speed can be comparable.

6. Low cost, 1/10 of the cost of laser.

7. Easy to use, easy to operate, CAD graphics directly into the code can be cut.

Main technical parameters

型号Model | MCQC-2040 | MCQC-2060 | MCQC-2080 | MCQC-2560 | MCQC-3060 | MCQC-3080 | MCQC-30100 | MCQC-30120 |

有效切割宽度 | 2000 | 2000 | 2000 | 2500 | 3000 | 3000 | 3000 | 3000 |

有效切割长度 | 4000 | 6000 | 8000 | 6000 | 6000 | 8000 | 10000 | 12000 |

标配割炬数量 | 1 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

轨道长度 | 4、6、8、10、12…… 轨道:2米/节 ,可任意选配轨道长度 | |||||||

割炬行程 | 150 | |||||||

切割厚度 | 火焰切割 Flame cutting:5 - 200 mm 等离子切割 plasma cutting:1 - 50 mm | |||||||

切割速度 | 火焰切割 Flame cutting:0 - 1000 mm/min 等离子切割 plasma cutting:0 - 5000 mm/min | |||||||

空程速度 | 0 - 6000 mm/min | |||||||

输入电源 | AC220 V/ 380 V 50HZ | |||||||

驱动方式 | 双边驱动 Bilateral drive | |||||||

机床驱动电机功率 | 800 W/ 2500W | |||||||

切割方式 | 火焰切割:氧气+乙炔、丙烷 等离子切割:压缩空气、氧气、氮气等 | |||||||

The form is for reference only, please consult the staff for more information

Product Features:

1. Desk type cnc drilling and cutting all-in-one machine is a set of computer control, precision mechanical transmission, thermal cutting in one of the efficient, high precision, high reliability of cutting equipment.

Good man-machine interface makes the operation more convenient and simple, can quickly and accurately cut out a variety of complex shape plate, especially suitable for medium, thin non-ferrous metal plate, stainless steel and carbon steel plate automatic blanking.

It adopts integrated modular design, fast installation, easy to move.

2. Vertical and horizontal guide adopts domestic or imported linear guide, with high precision and good guidance.

The longitudinal guide adopts special rail, the surface is ground and arranged externally, which has high mechanical precision and wear resistance.

Drive rack, gear customized by professional manufacturers.

Transversal and longitudinal transmissions adopt German NEUGART or Japanese high precision, high torque, low back clearance, maintenance-free planetary gear reducer.

3. Servo drive adopts Panasonic servo drive system with position detection function, high motion precision, wide speed range and short acceleration time.

4. Dust removal table or dust treatment device can be optional to create a good working environment.

5. A variety of plasma power supply can be selected to meet the requirements of different metal material cutting.

Results show