CNC Phase Inodes Cutting Machine

QGVI type NC intersecting line cutting machine is controlled by computer, driven by AC servo or step machine, four or two axes.

The intersecting line cutting of groove and non-groove pipe interface can be realized.

The equipment has a variety of cutting program memory function, cutting data track keeping function, track automatic demonstration function, automatic pipe detection, simulation tracking function, CNC automatic positioning, a variety of speed control, fixed Angle and variable Angle groove surface cutting energy.

The cutting machine system program is convenient and quick, the display interface is intuitive and simple, the cutting precision is stable and reliable, the equipment is widely used in petroleum, ship, steel structure, construction and other industries.

The cutting machine can cut carbon steel pipe and stainless steel pipe according to the needs of users by flame or plasma.

This cutting machine is very simple to operate, just input the pipe diameter of the main branch pipe, the form of intersection between the main branch pipe, intersection Angle and cutting speed and other parameters, then automatic cutting can be carried out.

You don't have to do complicated calculations.

In addition, it can cut a number of cylindrical intersecting line holes in different directions and diameters on the main pipe and cut the end of the cylindrical intersecting line at the end of the branch pipe, so as to meet the conditions of vertical intersection and inclined intersection between the branch pipe axis and the main pipe axis of eccentricity and non-eccentricity.

It also has the function of one-time clamping to cut several cylindrical intersecting line holes in different directions and diameters on the main pipe and one-time clamping to cut both ends of branch pipe.

This cutting machine can cut the groove surface at a fixed Angle and variable Angle according to the user's needs.

Cut and weld the oblique cutting surfaces at both ends of the "shrimp joints" of the elbow on the pipe, and also cut the oblique end faces at the end of the pipe with an Angle ≥25°(the included Angle with the axis of the steel pipe);

Or directly cut off the steel pipe.

The cutting machine can cut the end of the intersecting line of the branch pipe and the ring main pipe. It can also cut square hole and waist hole.

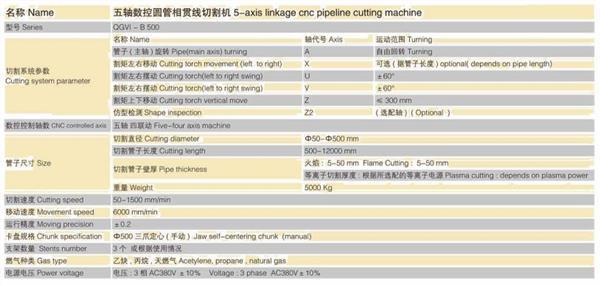

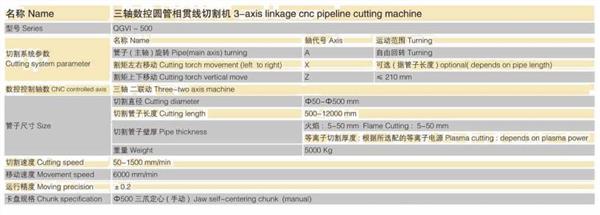

Main technical parameters

The form is for reference only, please consult the staff for more information.

The machine can be widely used in shipbuilding, construction, petrochemical, machinery, metallurgy and other industries of pipe structure cutting processing.

In these industries, there are a large number of pipelines combined with intersecting line holes and intersecting line ends, as well as elbows commonly known as "Shrimp section". Such processing is mostly carried out by backward and complicated methods such as template making, marking, manual lofting, manual cutting and manual polishing.

The JKx series CNC pipe cutting machine manufactured by our factory can cut this kind of workpiece very conveniently, and the operator does not need to program, just need to input the parameters such as the radius and intersection Angle of the mutually matching pipe, the machine can automatically cut out the intersecting line, intersecting hole and welding groove of the pipe, no longer need manual polishing.

Scope of Application

Products