Pipe Surface Grinding Buffing Polishing Machine

Pipe surface grinding buffing polishing machine is the main function of the surface polishing, deburring, and in addition to the scale, the cylindrical polishing technology is mature, the product of a high degree of automation, and the automatic polishing machine specially used for pipeline in the market at present is most suitable for the length of the smaller pipe, tube and tanks, or use blasting or sandblasting and other special polishing process, the equipment complex, high cost, maintenance is not convenient, so in some small and medium-sized manufacturers still use manual polishing, long processing time, product performance and quality is difficult to guarantee, at the same time the manual labor, work, boring and bad for workers' health.

At present, the special polishing machine for the pipeline with a larger processing diameter covers a larger area, and the feed is realized by the workpiece rotation, and some processing products are larger, the workpiece needs to be rotated when polishing, resulting in higher energy consumption, and the current energy-saving requirements do not meet, and can only polish a certain length of straight pipe.

It is important that when you polish the inside of the pipe, you cannot see what is going on inside, which may cause unnecessary damage.

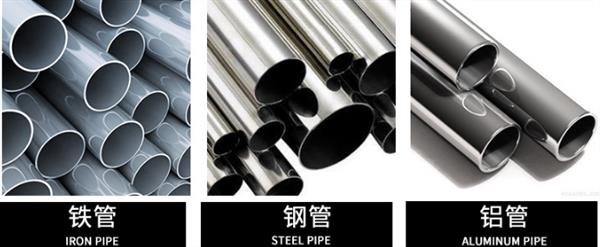

The equipment can be used for polishing, derusting, wire drawing, grinding, and peeling of pipes and bars of various materials, such as iron, copper, zinc alloy, aluminum alloy, stainless steel, titanium alloy, etc.

The machine features stable performance, small vibration, high efficiency, simple operation and easy maintenance.

The polishing machine is mainly used for the derusting and polishing of hardware manufacturing, vehicle accessories, steel and wood furniture, instrument machinery, standard parts and electroplating industries. It is the ideal choice for the polishing of round pipes, round sticks and slender shafts.

Multi - power external polishing machine.

Fine tube polishing machine, stainless steel square tube polishing machine, the main production of the round tube polishing machine will not affect the size of the workpiece, especially suitable for the centerless grinding machine after the workpiece high brightness polishing.

Cylindrical polishing machine has high efficiency, good surface roughness of workpiece, supply multi - power external polishing machine.

Fine tube polishing machine, stainless steel square tube polishing machine, stable performance, the regulating wheel speed frequency conversion control (optional), so no matter the workpiece diameter size, also can be processed to the ideal purpose.

It is an ideal choice for polishing round tube, round rod, slender shaft and quartz rod.

Pipe polishing machine parameters:

The machining diameter is 3-80mm,

Machining length: arbitrary,

Machining accuracy: 0.02mm,

Speed: 2800 RPM,

Weight 260 kg,

Total power 3.4 kw,

Power supply of 380 v,

Efficiency 2-12 m/min adjustable speed

Polishing wheel specification: 250*80*32mm,

External dimension: 860*880*850mm,

Regulating wheel speed is regulated by frequency conversion

The equipment can be used for polishing, derusting, wire drawing, grinding, and peeling of pipes and bars of various materials, such as iron, copper, zinc alloy, aluminum alloy, stainless steel, titanium alloy, etc.

The machine features stable performance, small vibration, high efficiency, simple operation and easy maintenance.