W12- Four Rollers Plate Rolling Machine

W12- Four Rollers Plate Rolling Machine Major parts of the manufacturing process :

Working rollers: cast steel ingot (chemical composition analysis): check performance-forging roughcast — forging annealing-UT flaw — roughing (mechanical tests)-heat treatment (hardening and tempering) — UT flaw — semi finishing — finishing — MT.

Large forgings: cylinder body, gear, gear shaft forging roughcast — surface inspection – roughing — UT flaw — UT flaw detector heat treatment — finishing semi—finishing — MT.

Welding structure: racks, chassis, wheel box

Plate into the factory (chemical composition analysis, mechanical properties test) — pretreatment — for sheet metal cutting-welding-seam UT or RT flaw — annealing treatment — roughing-finishing— vibration destressing—hot blasting —finishing

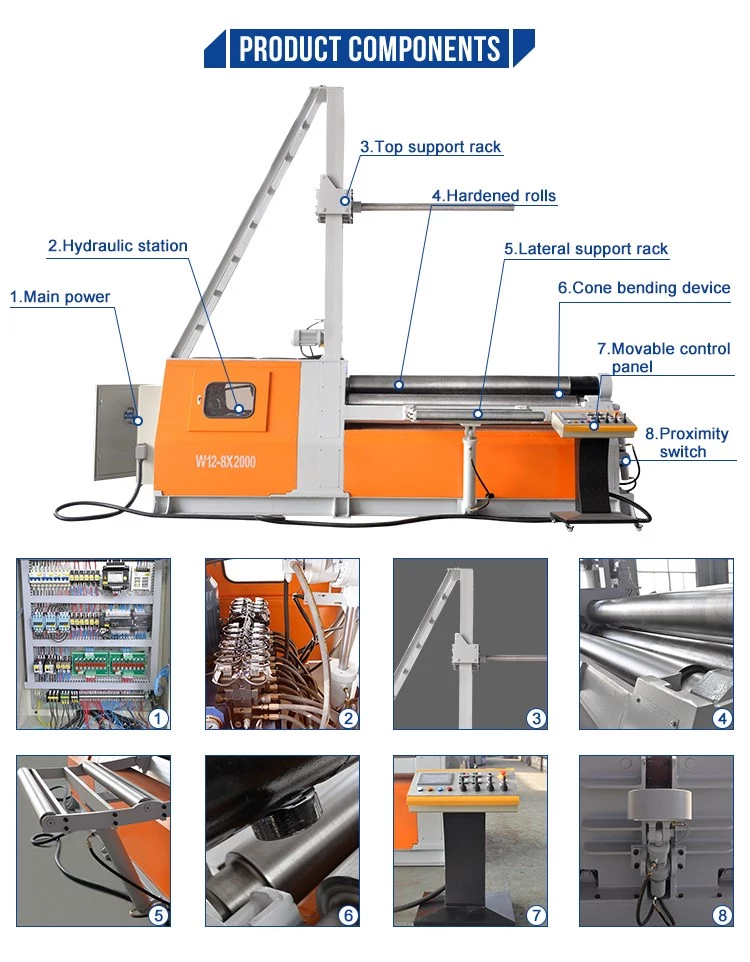

W12- four roller plate rolling machine Configuration of Hydraulic Plate Rolling machine is as follows:

Main power: Siemens Electrical made in Germany

Main electronic elements: Schneider made in France;

Axletree:Double-row self-aligning bearing from Germany

Main motor: Siemens Electrical made in Germany

Programmable logic controller PLC: OMRON products from Japan

Hydraulic system: Bosch – Rexroth made in Germany

Oill pump: Sunny from USA ;

Work Roller: Material of work roller with 42CrMo Alloy steel.

Digital display system: Touch Screen for Delta

Transducer: OMRON,Made in Japan

Automatic lubrication system: Sino-Japanese joint,which has block alarm

Product Model

Model型号 | Max bergulir ketebalan * panjang | Diameter Roll Utama | Bottom roll diameter下辊直径 | scroll speed滚动速度 | main motor主电机 |

MM | MM | MM | M/min | KW | |

W12-4x1500 | 4x1500 | 140 | 120 | 4 | 2.2 |

W12-4x2000 | 4x2000 | 160 | 140 | 4 | 2.2 |

W12-4x2500 | 4x2500 | 190 | 150 | 4 | 3 |

W12-4x3000 | 4x3000 | 210 | 170 | 4 | 7.5 |

W12-4x4000 | 4x4000 | 270 | 210 | 4 | 5.5 |

W12-6x2000 | 6x2000 | 190 | 150 | 4 | 5.5 |

W12-6x2500 | 6X2500 | 210 | 170 | 4 | 7.5 |

W12-8x1500 | 8x1500 | 200 | 170 | 4 | 5.5 |

W12-8x2000 | 8x2000 | 210 | 180 | 4 | 7.5 |

W12-10X2000 | 10x2000 | 230 | 180 | 4 | 7.5 |

W12-10X2500 | 10x2500 | 270 | 210 | 4 | 11 |

W12-12x2000 | 12x2000 | 245 | 200 | 4 | 11 |

W12-12x2500 | 12x2500 | 265 | 220 | 4 | 11 |

W12-16x2000 | 16x2000 | 250 | 210 | 4 | 15 |

W12-16x2500 | 16x2500 | 300 | 240 | 4 | 15 |

W12-20x2000 | 20x2000 | 300 | 250 | 4 | 18.5 |

W12-20x2500 | 20x2500 | 350 | 280 | 4 | 18.5 |

W12-25X2000 | 25x2000 | 360 | 250 | 4 | 15 |

W12-25X2500 | 25x2500 | 390 | 300 | 4 | 18.5 |

W12-30x2500 | 30x2500 | 410 | 340 | 4 | 22 |

W12-30x3000 | 30x3000 | 450 | 380 | 4 | 30 |

W12-35x2000 | 35x2000 | 430 | 330 | 4 | 30 |

W12-35x2500 | 35x2500 | 460 | 360 | 4 | 30 |

W12-40x2500 | 40x2500 | 500 | 420 | 4 | 37 |

W12-40x3000 | 40x3000 | 540 | 440 | 4 | 45 |

W12-45x2500 | 45x2500 | 460 | 420 | 4 | 30 |

W12-45x3000 | 45x3000 | 510 | 460 | 4 | 37 |

W12-50x2500 | 50x2500 | 560 | 450 | 4 | 45 |

W12-50x3000 | 50x3000 | 600 | 480 | 4 | 55 |

W12-60x2500 | 60x2500 | 610 | 500 | 4 | 55 |

W12-60x3000 | 60x3000 | 650 | 520 | 4 | 75 |

W12-65x3000 | 65x3000 | 650 | 550 | 4 | 55 |

W12-85x3000 | 85x3000 | 760 | 680 | 4 | 75 |

The form is for reference only, please consult the staff for more information

W12- Four Rollers Plate Rolling Machine Main Features:

Totally European design,streamlined looking,frames of our machines are fabricated, welded steel (ST-52). Roll shafts, materials and bearings used in production are European quality. Also the torque limit of the machines is very high. CNC playback and CNC graphic control systems are available as optional accessory.

The main structure of the equipment includes upper roller, lower roller and horizontal movement mechanism, supporting mechanism,main drive mechanism,downturn system, left and right machine frame, chassis and balance mechanism, hydraulic and electrical control systems.

The model MH has both the upper and the lower roll powered with hydraulic motor and planetary gear box.

High precision pre-bending, freely setup the width of plate. Upper roller presses the plate end for pre-bending.

Upper roller likes drum with collaboration of carrier roller permit continual bending of any thickness of plate.

Safe work, fixed two down roller, upper roller does horizontal and vertical movement, and the plate don’t move during upper roller moving.

Unitary structure, convenient to move the whole machine as machine has a hardy under pan. No need to anchor bolt.

Different use has different control way, like top numerical control and below numerical control.

Through exclusive technology, Krrass can develop cones as easily as competitive machines can develop cylinders. And it eliminates scarring on the surface of shell or roll and also eliminates, in most cases, the need for grinding the lamination (bullnosing) on the minor diameter edge.