WC67K-Hydraulic Servo Press Brake CNC Plate Bending Machine

WC67K-Hydraulic Servo Press Brake CNC Plate Bending Machine Product introduction

The frame is welded with steel plate as a whole, with proper appearance and standard, and sufficient strength and rigidity.

Choose reliable electro - hydraulic proportional servo valve synchronous organization.

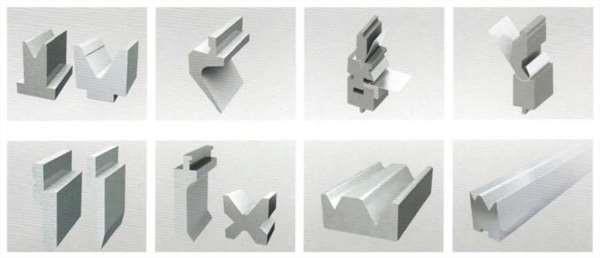

Randomly equipped with a set of standard upper and lower molds (can supply special molds according to the practical needs of users)

Italian ESA/GV numerical control system, this is the real sense of the bending machine NUMERICAL control system.

Complete function, reliable performance, very convenient to use.

Together with the office PC CNC bending machine software gifts, so that the office computer and the CNC bending machine communication system.

DELEM NUMERICAL control system of The Netherlands and ESA numerical control system of Italy (optional according to the customer's own needs)

Control the number of axes (3+1 axis) Y1, Y2 axis -- up and down movement of the slider (electro-hydraulic servo valve) X axis -- back and forth movement of the rear baffle (servo motor) V axis -- table with convex

Dutch DELEM NUMERICAL control system

10.2 TWO-DIMENSIONAL colorful LIQUID crystal display

2 D graphics programming, on a page can end direct programming and graphics programming, active programming bending process, and imitate each work step.

Direct programming -- directly input the scale and Angle of each working step;

Graphic programming - press the direction key to directly draw the finished piece of graphics

Strong ability to calculate and control, active correction ability - bending force - work table plus convex - large arc, blanking die - slider speed conversion point, compression point, bottom dead point - bending force, deflection compensation force, bending Angle, compression point, fast and slow speed conversion, the end of active correction

The total working step capacity is more than 10000

Data will not be lost when power is cut off or the machine is shut down between winks

Main configuration

Rack, oil cylinder and rear stopper are supplied by professional factory

Electro-hydraulic proportional servo valve assembly -- HOERBIGER, Germany

CNC system -- DELEM CNC System of The Netherlands (optional according to customer requirements)

Servo motor (including encoder) -- Yaskawa, Japan

Grating ruler - GIVI, Italy

Structure of machine tool

A. Adopt all-steel welding frame, vibration aging treatment, with sufficient strength and rigidity.

B. Double cylinder control, mechanical block mechanism protection, hydraulic upper transmission, torsional shaft forced synchronization mechanism.

C. The slider stroke is quickly adjusted by electric motor, with manual fine adjustment and display by display

D. The upper die is equipped with an oblique wedge deflection compensation mechanism to supplement the bending accuracy.

Multi-machine linkage can be carried out (additional linkage synchronous device is needed)

WC67K series hydraulic servo CNC plate bending machine Specification and model:

型号 | 公称压力 | 工作台长度 | 立柱间距 | 喉口深度 | 滑块行程 | 最大开启高度 | 主电机功率 | 外形尺寸 |

(KN) | (mm) | (mm) | (mm) | (mm) | (mm) | (KW) | (mm) | |

WC67K-40t/2200 | 400 | 2200 | 1775 | 250 | 100 | 320 | 5.5 | 2300×1500×2000 |

WC67K-40t/2500 | 400 | 2500 | 1975 | 250 | 100 | 320 | 5.5 | 2600×1500×2000 |

WC67K-63t/2500 | 630 | 2500 | 2095 | 250 | 120 | 360 | 5.5 | 2600×1600×2300 |

WC67K-63t/3200 | 630 | 3200 | 2570 | 250 | 120 | 360 | 5.5 | 3300×1600×2300 |

WC67K-80t/3200 | 800 | 3200 | 2565 | 320 | 120 | 360 | 7.5 | 3300×1700×2300 |

WC67K-80t/4000 | 800 | 4000 | 3165 | 320 | 120 | 360 | 7.5 | 4100×1700×2300 |

WC67K-100t/3200 | 1000 | 3200 | 2560 | 320 | 120 | 360 | 7.5 | 3300×1800×2400 |

WC67K-100t/4000 | 1000 | 4000 | 3165 | 320 | 120 | 360 | 7.5 | 4100×1800×2500 |

WC67K-125t/3200 | 1250 | 3200 | 2550 | 320 | 120 | 360 | 7.5 | 3250×1920×2450 |

WC67K-125t/4000 | 1250 | 4000 | 3450 | 320 | 120 | 360 | 7.5 | 4100×1920×2500 |

WC67K-160t/3200 | 1600 | 3200 | 2540 | 320 | 180 | 440 | 11 | 3300×1600×2600 |

WC67K-160t/4000 | 1600 | 4000 | 3140 | 320 | 180 | 440 | 11 | 4100×2000×2600 |

WC67K-160t/6000 | 1600 | 6000 | 4740 | 320 | 180 | 440 | 11 | 6100×2000×2600 |

WC67K-200t/3200 | 2000 | 3200 | 2540 | 320 | 250 | 530 | 11 | 3300×2100×2800 |

WC67K-200t/4000 | 2000 | 4000 | 3140 | 320 | 250 | 530 | 15 | 4100×2100×2900 |

WC67K-200t/5000 | 2500 | 5000 | 3120 | 400 | 250 | 530 | 15 | 5100×2100×3000 |

WC67K-250t/4000 | 2500 | 4000 | 3120 | 400 | 250 | 560 | 18.5 | 4100×2200×3500 |

WC67K-250t/5000 | 2500 | 5000 | 3920 | 400 | 250 | 560 | 18.5 | 5100×2200×3500 |

WC67K-250t/6000 | 2500 | 6000 | 4720 | 400 | 250 | 560 | 18.5 | 6100×2200×3500 |

WC67K-300t/5000 | 3000 | 5000 | 39100 | 400 | 250 | 560 | 22 | 5100×2600×4000 |

WC67K-300t/6000 | 3000 | 6000 | 4710 | 400 | 250 | 560 | 22 | 6100×2600×4000 |

WC67K-300t/7000 | 3000 | 7000 | 5620 | 400 | 250 | 560 | 22 | 7100×2600×4400 |

WC67K-350t/6000 | 3500 | 6000 | 5100 | 400 | 250 | 560 | 30 | 6100×2600×4200 |

WC67K-350t/7000 | 3500 | 7000 | 5620 | 400 | 250 | 560 | 30 | 7100×2600×4500 |

WC67K-400t/4000 | 4000 | 4000 | 3100 | 400 | 300 | 620 | 30 | 4100×2700×3800 |

WC67K-400t/6000 | 4000 | 6000 | 4280 | 400 | 320 | 630 | 30 | 6100×2800×4200 |

WC67K-500t/5000 | 5000 | 5000 | 4100 | 400 | 320 | 630 | 37 | 5100×3000×4400 |

WC67K-500t/6000 | 5000 | 6000 | 4820 | 400 | 320 | 630 | 37 | 6100×3000×4700 |

WC67K-500t/7000 | 5000 | 7000 | 5620 | 400 | 320 | 630 | 37 | 7100×3000×4900 |

WC67K-600t/6000 | 6000 | 6000 | 4820 | 400 | 320 | 630 | 45 | 6100×2965×4700 |

WC67K-600t/7000 | 6000 | 7000 | 5620 | 400 | 320 | 630 | 55 | 7100×2965×4900 |

The form is for reference only, please consult the staff for more information

Main Features of our bending machine:

1.EU standard design and make

2.Multi-work-step programming function

3.Friendly CNC controller and low cost hydraulic maintenance.

4.High quality synchronized cylinders and valves.

5.Automatic axis referencing and calibrating

6.High bending precision of 0.01 mm

7.Long lasting stiffened top and bottom tool brands

8.Silent high pressure pump.

9.Special numeric-control system is fitted with mainframe of the bending machine

10.Multi-work-step programming function is able to achieve an automatic operation and continuous positioning of multi-step procedures,as well as an automatic precision adjustment for positions of rear stopper and gliding block.

11.The bending machine is povided with bend counting function,for a real-time display of processing quantity and power-failure memory of positions of stopper and gliding block,as well as procedures and parameters.

12.Imported ball bearing lead screw and linear guide rail are used for rear stopper,to ensure the positioning precision of rear stopper,for processing precision of machine to be higher.

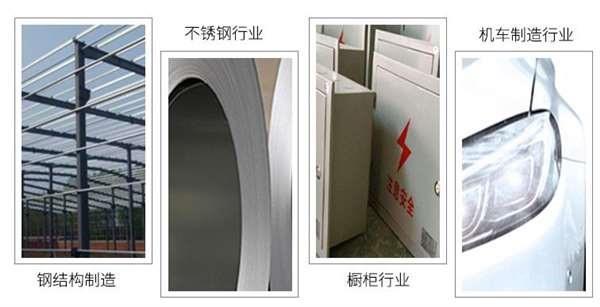

1.The application of our bending machine

Our bending machine has high productivity and high working accuracy, using different shapes of up and down mould, can be bent into various shapes artifacts, slider stroke at a time can be to a bending forming of sheet metal,after a lot of bending can be achieved relatively complex shape workpiece, when equipped with the corresponding equipment, can also make a punch

2. The structure of our bending machine

Using UG (fem) analysis method, the computer aided optimization design, beautiful appearance

2). The fuselage USES the steel plate welded structure, with sufficient strength and stiffness, hydraulic transmission to ensure work is not due to the thickness of the sheet metal change or die "V" shaped groove choose undeserved and cause serious overload accident, in addition the machine working smoothly, with convenient operation, low noise, safe and reliable, etc

3. The performance Characteristics

1). This bending machine adopts hydraulic electric control, sliding block stroke can be adjusted, and have some fixed, semi-automatic, automatic movements such as norm, using dynamic specification can easily test and adjustment

2). lift brake press design, double oil cylinder work at the same time, balance, convenient operation, safety

3). The dead point have confirmed when rolling function, ensure that the workpiece precision

Apply to industry