New Order from Argentina: Automatic Girth Welding Machines

Release Time : 2025-06-06 View Count : 次Successful Project in Argentina: Automatic Girth Welding Machines Enhance Industrial Production

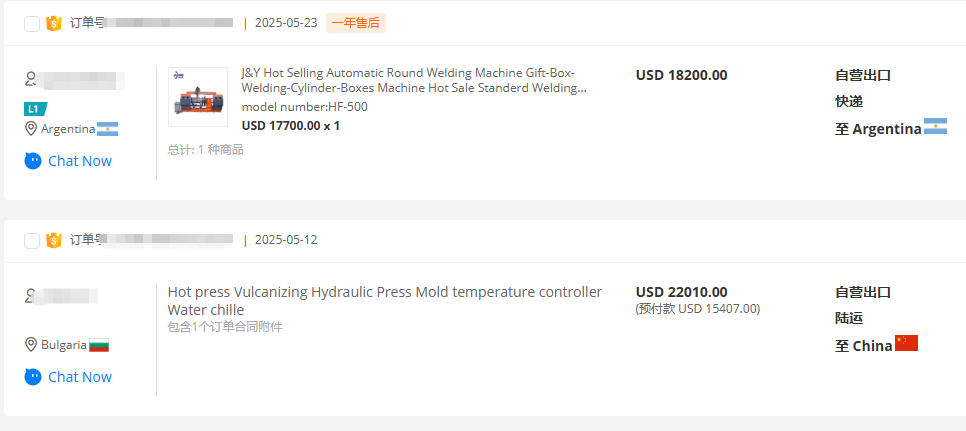

Dalian Mingcheng Machinery Equipment Co., Ltd. has successfully secured and completed a new overseas project in Argentina, supplying advanced Automatic Girth Welding Machines to a local industrial manufacturer. This cooperation further strengthens Mingcheng’s presence in South America and demonstrates growing global demand for stable and efficient welding automation solutions.

Client Background and Application Overview

The Argentine client is a professional manufacturer serving the pressure vessel, valve, and pipeline fabrication industries. Its products are widely applied in energy, chemical processing, and infrastructure construction, where welding accuracy and consistency are critical to safety and compliance.

Prior to cooperation with Mingcheng, the customer faced several production bottlenecks:

High dependence on experienced manual welders

Inconsistent weld quality during batch production

Rising labor and training costs

Difficulty meeting RT and UT inspection standards

After evaluating multiple suppliers, the client selected Mingcheng Automatic Girth Welding Machines for their proven stability, precision control, and long-term operating efficiency.

Automatic Girth Welding Technology

Mingcheng’s automatic girth welding system integrates advanced arc welding technology with CNC-controlled automation, delivering highly repeatable, accurate, and uniform weld seams for circular components.

Core Technical Features

Programmable intelligent control system

Real-time adjustment of current, voltage, welding speed, and torch position ensures consistent weld quality.- High-energy compressed arc technology

Achieves weld penetration up to 6 mm while reducing the heat-affected zone by approximately 40%. - Dual-end clamping and synchronized rotation

Maintains excellent stability and concentric accuracy throughout the welding process. - High-precision torch positioning

Allows fine adjustment accuracy up to 0.1 mm for demanding industrial applications. - Optional swing welding module

Optimized for V-groove and multi-layer welding on thick-walled components. - Integrated gas shielding and flux recovery system

Ensures stable weld protection while reducing material consumption.

Performance Results and Customer Benefits

Following installation, commissioning, and operator training, the Argentine customer reported clear and measurable improvements in productivity, weld quality, and cost control.

Typical Application Improvements

Valve manufacturing: welding time reduced from approximately 10 minutes to 1.5 minutes per unit.

Large industrial structures: multi-layer welding completed up to 15 times faster than manual methods.

Energy and pressure systems: improved weld integrity meeting strict safety standards.

Industry Outlook and Future Trends

This project reflects the ongoing transformation of welding automation toward higher intelligence and sustainability. Multi-machine coordination, low-heat-input welding processes, and mobile robotic systems are becoming standard solutions across heavy equipment manufacturing.

About Dalian Mingcheng Machinery Equipment Co., Ltd.

Founded in 2012, Dalian Mingcheng Machinery Equipment Co., Ltd. specializes in CNC machine tools and automated welding equipment. With a modern manufacturing base of 66,600 m² and an annual capacity of 50,000 sets, Mingcheng serves customers across the United States, Europe, South America, the Middle East, and Asia.

Guided by a customer-first philosophy and continuous innovation, Mingcheng is committed to becoming a long-term, reliable partner for global industrial automation solutions.