Influence of press brake deformation compensation device on accuracy

Release Time : 2022-08-23 View Count : 次Why does a press brake need a compensation device?

When the press brake bends the workpiece, the slider and the table will be deformed under the action of the bending force. At this time, the depth of the upper die entering the opening of the lower die is inconsistent over the entire length of the workpiece, which will seriously affect the accuracy of the workpiece.

For this reason, various structures of deformation compensation devices have been developed. It is roughly divided into two categories: one is a set of symmetrical curves that protrude the worktable into an upward bulge in the middle, which is called lower die plus convex compensation; Symmetrical curve, called upper die plus convex compensation.

Two types of different compensation devices can effectively reduce the angle error of the bending part. But there is a difference in the effect on straightness.

Natural deflection of bent parts

After the sheet is bent, the edges of the bent parts will naturally deflect. Usually, it is expressed by its maximum deflection.

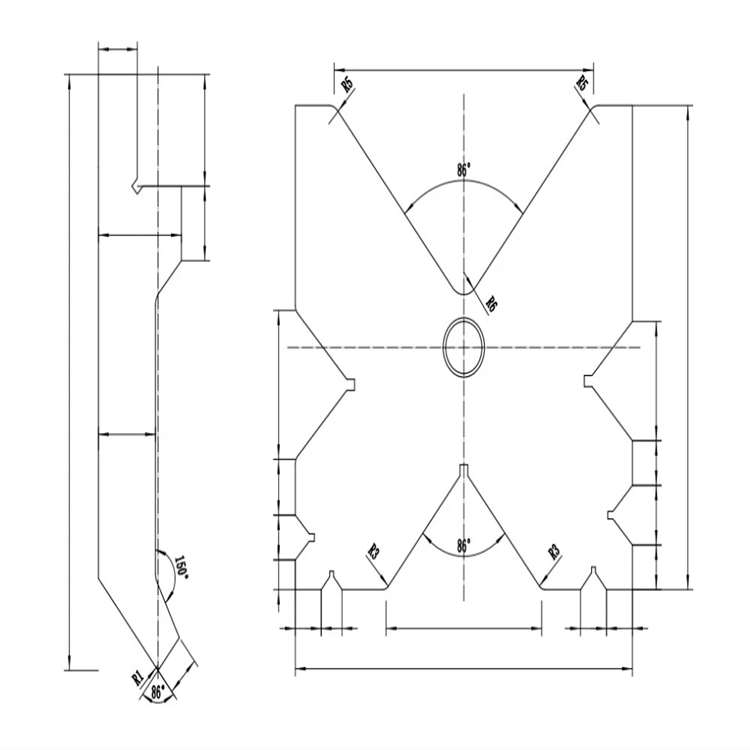

When the sheet metal is bent, the metal in the bending deformation zone is in a highly plastic deformation state, and the inner layer of the arc in the deformation zone generates longitudinal compressive stress parallel to the OX direction, and the outer layer is longitudinal tensile stress.

These two opposing stresses in tension and compression form a longitudinal moment My that rotates about the OY axis. It is the moment required to keep the longitudinal direction (direction) of the bending part consistent with the longitudinal line corresponding to the mold when the sheet is bent.

After the bending, the slider returns, the bending force and the longitudinal moment disappear at the same time, and each metal layer in the deformation zone rebounds immediately, forming a bending in the longitudinal direction opposite to the longitudinal moment, that is, natural deflection.

For the convenience of expression, the bending deformation region is expanded into a plane here. Under the action of the bending force, the upper layer (the inner layer of the arc) is longitudinally compressed, and the lower layer (the outer layer of the arc) is pulled.

Influence of Two Different Convex Compensation Methods on Straightness of Bending Parts

When the lower die is added with convex compensation, the curve for compensation of convex amount will bulge upwards. When convex compensation is added to the upper die, the curve with convex amount is bent downward.

The change curve of the natural deflection of the bending part is an upward bulge. The amount of compensating convexity depends on the deformation of the slider and the table when bending, and its value is small. Compensating the convex amount makes the convex deflection formed by the bending part to be somewhat reduced when the springback is unloaded. This results in a deflection that is generally lower than the natural deflection of the bent part.

Comparative Analysis of Four Common Compensation Devices

1) The lower beam hydraulic cylinder adds convex compensation

After the oil cylinder is passed through the pressure oil, the beam will bulge upward to form a set of controllable convex curves. It has been widely used in CNC press brake. Its characteristics:

The oil cylinders are evenly distributed in the beam, and the convex curve is close to the deformation curve of the slider and the table over the entire length of the table. The convex amount is controlled by the hydraulic system pressure, which is convenient and quick to operate. It can improve the accuracy of the bending angle of the workpiece. The structure is more complex and the cost is high.

2) Convex compensation of wedge block in worktable

Several groups of wedges are installed under the workbench, and the bevel angle of each group of wedges is designed according to certain requirements. The horizontal position of the upper wedge of each group of wedges is fixed, and the lower wedge moves to the left at the same time, and the working table rises upwards according to the design requirements. It has been widely used in various types of press brake.

Its features:

The wedges are evenly distributed in the worktable, and the convex curve is designed as the deformation curve of the slider and the worktable, and the convex compensation is more accurate. @Use the moving length of the lower wedge to control the amount of convexity, which can be manual or motorized, and is easy to operate. It can improve the accuracy of the bending angle of the workpiece.

3) Convex compensation for upper die wedge

There are multiple sets of wedges between the slider and the upper die, and the specifications of each set of wedges are the same. The connecting plate and the lower wedge of the wedge are fixed as a whole, move the upper wedge to obtain a downward bulging convex curve, and finally use the pressure plate to fix them between the slider and the upper die.

Its features:

The wedges are evenly distributed under the slider. By adjusting each wedge, the best convex curve can be obtained. The structure is simple and the cost is low, but the operation is inconvenient. It is widely used in medium and small ordinary press brake after precise adjustment. , can effectively improve the accuracy of the bending angle of the workpiece, and the straightness of the workpiece is better.

4) The slider hydraulic cylinder adds convex compensation

A group of oil cylinders are arranged in the middle of the slider. After the cylinder is filled with pressure oil, the middle of the slider bulges downwards, forming a controllable local convex curve. Due to structural limitations, effective convexity cannot be obtained on both sides of the slider, and this compensation method has not been widely adopted.

Its characteristics are: the convex compensation is concentrated in the middle of the slider, and a reasonable convex curve cannot be formed on the full length of the upper die; the convex amount is controlled by the hydraulic system pressure, and the operation is convenient and fast; the angle and straight line of the workpiece can be appropriately improved. degree accuracy.

When the press brake is working, the amount of convexity for deformation compensation should be equal to the amount of deformation of the slider and the table, which requires that the amount of convexity compensation can be adjusted on the full length of the mold, which is convenient and quick to adjust. However, it is difficult for the currently applied structure of the upper die and convex compensation to achieve this requirement, which limits its application range. In order to improve the working accuracy of the press brake, give full play to the advantages of the upper die plus convex compensation, and develop a new structure for quickly regulating the increase of the upper die, it is one of the future development directions of the press brake. At present, some departments have made useful attempts in this regard and achieved good results.