Heavy presses are almost "monopolized" by China! What is so special about the Chinese press?

Release Time : 2020-10-14 View Count : 次What is the principle of a heavy press?

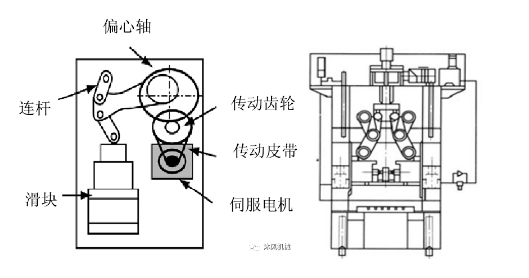

The press mainly relies on the motor to provide the power source. Through the transmission mechanism, it acts on the crank slider mechanism. The slider is often installed with the upper mold, the lower mold is installed under the working table, and the workpiece is placed in the middle. Under the pressure of the press, the The workpiece is pressed into the shape between the upper mold and the lower mold.

How to press?

In fact, the action process of a heavy-duty press is quite complicated, and it is not simple to press down. This process requires precise control of the pressure. For different materials, different structures and different processes, the required pressure control is also different.

For example, when the deep drawing is near the end point, the slider should be controlled to slow down to reduce the forming speed of the workpiece to prevent the workpiece from cracking, and reciprocate several times at a relatively low speed, and stop holding pressure for a period of time at the bottom dead center position Time can effectively improve the rebound phenomenon of sheet metal and greatly improve the forming accuracy.

From the perspective of kinematics, mechanical presses generally consist of three parts, namely input movement, transmission mechanism and output movement. The displacement, speed, force, etc. of the slider are all output motions. Changing the speed of the slider is to control the output motion.

How is the power transmitted?

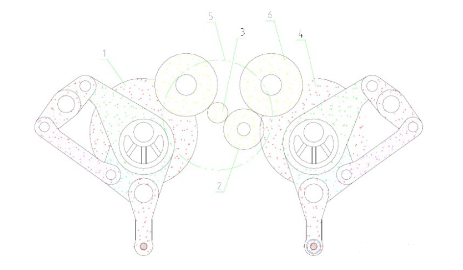

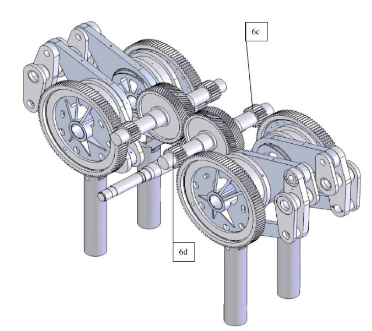

The motor power is transmitted to the flywheel 5 through the belt, and then the power is transmitted to the idler gear 2 through the pinion 3, and the idler gear 2 is transmitted to the gear shaft 6 through gear meshing, and the power is transmitted through the pinions 6c and 6d at the end of the gear shaft 6 To the eccentric 4. On the other side, the pinion 3 directly transmits power to the left gear shaft 6, without the need for an idler to change the transmission direction. Finally, driven by the two eccentric wheels, the multi-link mechanism moves, and the slider drives the upper mold to move.

It can be seen that the eccentric main drive drives the eight-bar linkage structure, so that the sliding stroke speed is low and uniform, the return speed is fast, and the precision compensation adjustment device is set, the transmission is stable, and the noise is low.

1 Eccentric wheel 2 Idler gear 3 Pinion gear 4 Eccentric wheel 5 Flywheel 6 Gear shaft

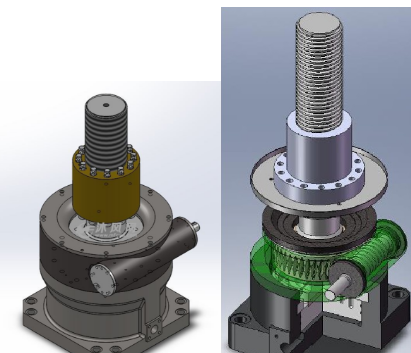

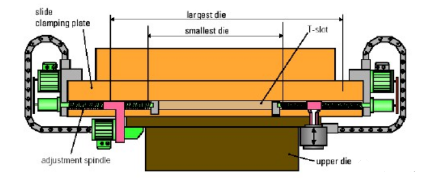

How is the power connected to the upper die?

The power output end is connected with the connector, the connector is connected with the clamping mechanism, and the clamping mechanism finally clamps the upper mold to ensure that it does not fall off.

It can be seen that a worm gear drive system is installed on the connector, which is called a slider adjustment mechanism, whose main function is to adjust the height of the mold. Among them, when adjusting the mold mounting height, a combination of a motor and a gearbox is often used, and a resolver is installed, which can digitally display the mounting height.

What is the mold balancer system?

The molds of heavy-duty presses are often heavy. The balance mechanism of the mold can effectively solve the problems caused by the heavy mold. According to the cross-sectional view of the balancer, air pressure can be applied to the piston to balance the upper die and the connecting slider, and the air pressure fluctuation during the movement can be reduced through the air tank of the balancer to ensure the stability of the movement.

The balancer can also control the gear meshing gap existing in the traditional system, reducing transmission wear. In addition, the piston and air pressure inside the balancer can ensure the smooth operation of the mold and effectively improve the working accuracy of the press.

The balancer can ensure that in the case of brake failure, reverse working resistance is provided to avoid sudden drop of the mold due to loss of control. At the same time, under the damping action of the balancer, it can improve the work of the brake, reduce the load, and ensure the reliability of the brake.

What is the function of the overload protection system?

If the pressure device has control errors or other failures, it may cause excessive pressure, which will directly damage the mold, and even directly cause damage to the press and personal injuries. The overload protection system is to find that the pressure load of the press exceeds 110%, and it can effectively unload to avoid accidents.

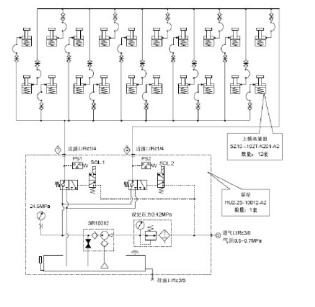

Overload protection is actually a set of hydraulic protection system, which is mainly composed of pneumatic pump, unloading valve, unloading oil tank, hydraulic cushion, control valve and pipeline. If an overload occurs, the pressure in the hydraulic cylinder rises sharply, and the pressure in the high pressure chamber of the unloading valve is greater than the back pressure in the back pressure chamber, pushing the piston down to open the oil