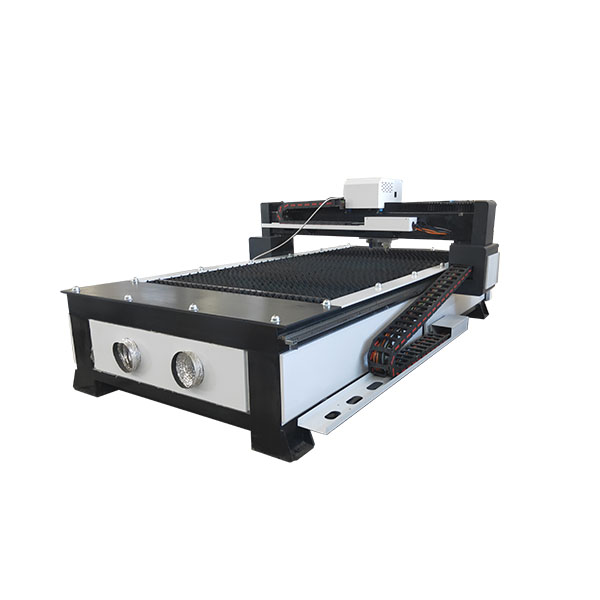

Cnc Stainless Sheet Metal Fiber Laser Cutting Machine

Fiber laser cutting machine

New Series fiber laser cutting machine is a high performance thin sheet metal laser cutting machine with 1000w/1500w/2000w/3000w fiber laser optional. It is suitable for cutting all thin metals, such as stainless steel, carbon steel, galvanized steel, aluminum, brass, etc. After redesign, New Series can provide larger effective strokes up to 3100*1600mm.

Product Details

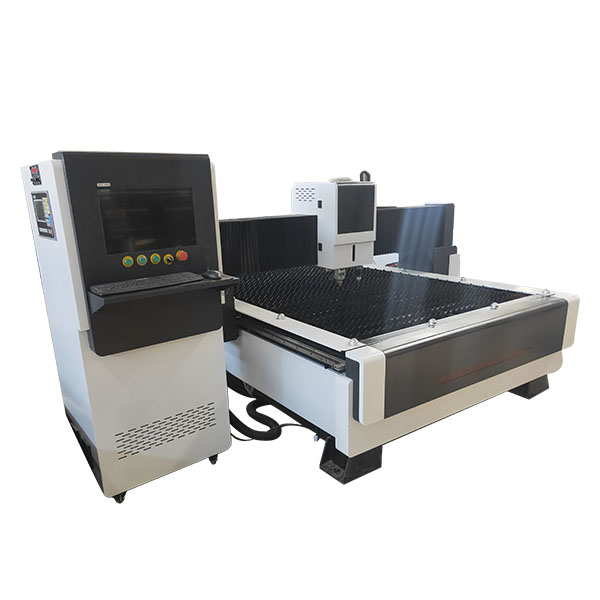

Main configuration:

1 Professional cypcut control system

2 Japan 750w Fuji servo motor with brake

3 100% genuine 25 Hiwin

4 Overall cast aluminum weighing design, faster and more accurate operation

5 Heavy-duty body, with multi-faceted professional vacuum duct holes

6 Industrial computers with long screens are more convenient to use and more in line with the habit of using mobile phones

7 Swiss raytool laser head with red light positioning operation is more stable and convenient

8 China famous brand, The MAX laser laser,

9 Japan shimpo reducer, is more accurate, faster and more stable.

10 Chinese famous brand S&A dual cooling chiller is more professional and can work for a long time.

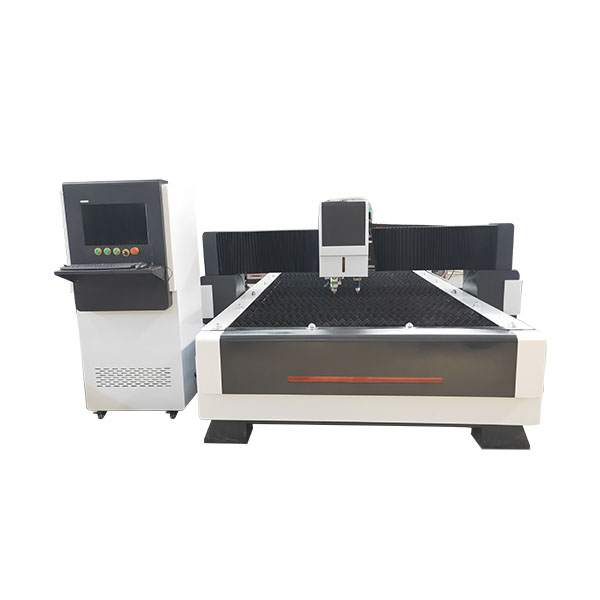

11 Luxury models are fully surrounded by sheet metal, and put in the workshop to enhance the level of the factory.

12 Pressure-resistant and explosion-proof water pipes and air pipes ensure the safe and stable operation of the machine under special circumstances.

13 High-precision grinding rack to ensure higher accuracy.

14 Fully enclosed fire protection is a high and low temperature towline, which ensures the safety of the operation site.

15 X Y axis flame retardant dust cover.

16 France Schneider Electric electrical components

17 Highly flexible, anti-breaking, cable that can shield external interference signals

18 Fully automatic oiling system

19 Easy-to-feed bull's eye wheel

20 High-strength body leveling feet, more suitable for different customer sites , To ensure high-quality running cutting

21 Professional serrated blade (with anti-scratch iron plate function)

22 Air cushion film fresh-keeping film pearl cotton three-layer soft packaging standard

23 No less than 1500w (high pressure proportional valve, automatic mixed oxygen and other The volume and pressure of the gas, thus more convenient operation)

Professional cypcut control system

High strength tube welding machine

Sheet cutting

It can be specially used for 0.5-16mm carbon steel plate, 0.5-16mm stainless steel plate, galvanized plate, cold-rolled plate, electrolytic plate, 0.5-10mm aluminum alloy plate, 0.5-10mm brass and copper and other metal materials.