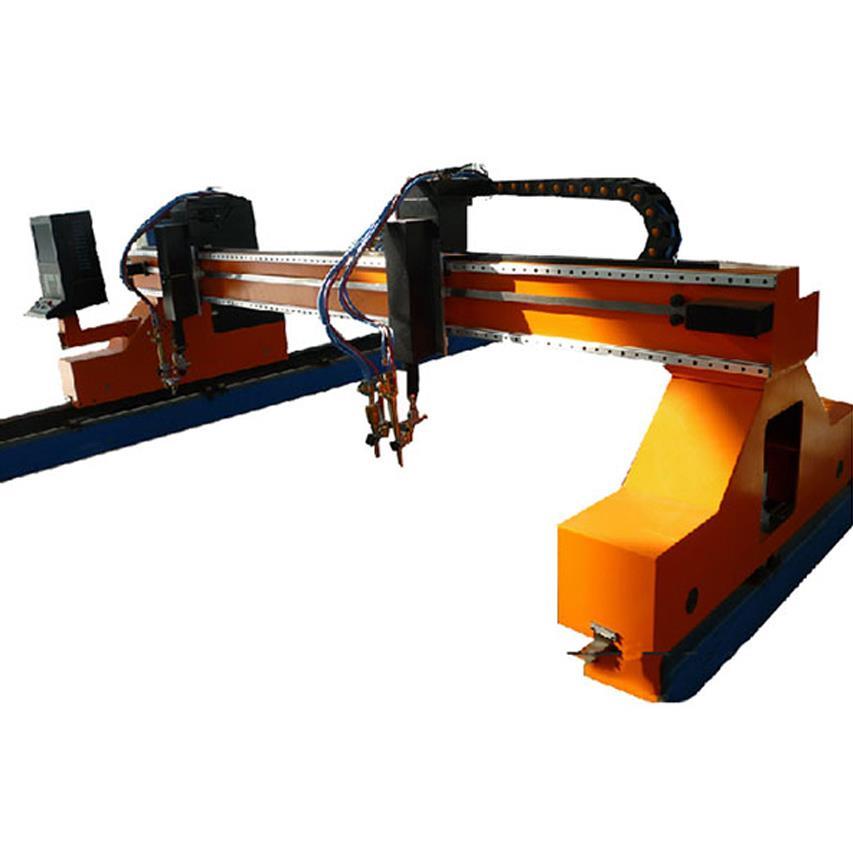

Economical gantry type CNC plasma cutting metal machine use gas available

Gantry cutting machine for gantry structure, transverse span of 3m, 4m, 5m, 6m, 8m and other specifications, are driven by bilateral, stable operation, good configuration, high efficiency, can be used for a variety of carbon steel, manganese steel, stainless steel and other metal materials of large, medium and small steel plate cutting.

Also can be configured according to the requirements of users more cutting torch, or configured into special-shaped cutting and straight cutting dual-use cutting mode, can also be optional with capacity or plasma automatic leveling system.

Product details:

Longitudinal drive control system:

Longitudinal use of double pinion rack meshing drive, equipped with a high precision reducer, plus speed and position feedback, to achieve high precision positioning drive.

Lateral drive control system:

The high precision single axle guide rail is adopted to realize the smooth movement of the same image and mirror image between the master and slave cutting torch through the steel wire device.

Pneumatic transmission mode:

In the longitudinal movement direction of the machine, there are many working cables, grounding cables and air sources, so the longitudinal movement of the load is very large, which will affect the running stability and reliability of the machine. The use of a trailing chain following mechanism ensures the cleanliness of the pipeline, and can reduce the overrushing tendency of the machine in the high-speed turning bay.

It can prevent the wear of the pipeline caused by high-speed cutting movement, and save unnecessary pipeline length at the same time.

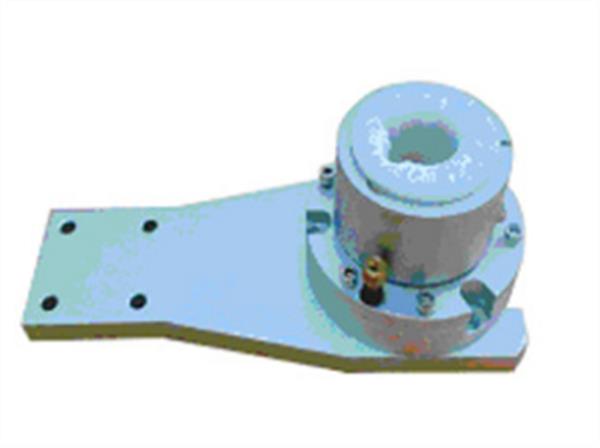

Plasma cutting torch anti-collision device:

The 360° anti-collision mechanism is controlled by sensors. Once the plasma torch is hit in any direction, the machine will stop moving immediately.

Technical index of gantry cutting machine

1. Cutting shape: programmable cutting any planar shape steel plate parts composed of straight lines and arcs;

2. Cutting accuracy: National standard JB/T10045.3-99;

3. Cutting width: 4m, 5m, 6m and other specifications optional;

4. Track length: 6 meters is standard, and 3m/ section extension can be customized according to user requirements;

5. Driving mode: bilateral driving;

6. Cutting torch configuration: 1 torch is standard, optional flame or plasma torch, and can also be customized according to user requirements;

7. Cutting thickness: the maximum flame cutting is 200mm, and the plasma cutting thickness depends on the size of the selected power supply;

8. Ignition elevation: automatic ignition, electric elevation, optional capacitor or arc voltage automatic elevation according to user requrements;

9. Numerical control system: easy to use, stable performance;

According to the requirements of users can choose Beijing State 2000 or 3000 system, imported haibao system,FastCNC CNC CNC system.

10. Numerical control programming: Automatic graphic programming software based on AutoCAD;

11. Cutting gas: Oxygen + acetylene or propane.

Shanghai Jiao Tong University (Fang Ling) F2300B

● Adopt two-axis digital control mode

● DPS control structure (more stable and reliable operation)

● Suitable for oxygen gas, plasma, laser cutting and other processing industries

● Easy to operate with a menu or graphical prompt

● Chinese, English, Spanish, Portuguese, French, Russian, Denmark.

● Korean, Japanese and other language menu one-button switch.

●47 commonly used graphics libraries (including grid graphics) can be set in size

● Support EIA code (G code) and various nesting software

● Control axis number: 2-axis linkage (3-axis customization)

● Control accuracy: 0.001mm soil

● Coordinate range: soil 9999.99mm

● Maximum pulse frequency: 200KHz Maximum operating speed: 15m/min

● Equipped with 10.4-inch 800*480 high resolution 160-million color color high brightness LCD screen

● Memory: 64M SDRAM

●USB: USB1.1 interface front, at least 16GB USB flash drive support

● Keyboard: PCB coated keyboard

Case: completely shielded with steel structure, it can truly prevent electromagnetic radiation, anti-interference and anti-static

● Working environment: temperature: -10C to +60C;

Relative humidity 0-95% no condensation

Panasonic servo Drive system in Japan:

Good speed control characteristics, in the whole speed zone can achieve smooth control, almost no shock, improve the efficiency of more than 90%.

No heat, high speed control.

High precision position control, within the rated operation area, achieve constant torque, high silence, no wear of brush, no maintenance, no wear particles, no spark, suitable for dust-free workshop, explosion-prone environment, low inertia.

Newcat reducer:

A lifetime of non-replaceable lubricants is used, so no maintenance is required no matter where it is installed.

Fully enclosed design, and with IP65 protection degree.

Therefore, it can also be used in poor working environment.

Can be used on standard motors without high centrality and output shaft seal.

Low backgap grinding gear meshing, so that low distance running, transmission ratio integer load evenly distributed across the three planetary gears, with a high torsional stiffness.

Planetary gearboxes are very efficient.

A noise optimized gear pair is used for very low noise level.

Low inertia, high dynamics.

Compact structure and light weight.

The support of the belt pulley can bear high radial load, so the belt pulley can be mounted directly.

The installation location shall be determined as required.

The connection mode of output terminal shall be determined as required.

The optical shaft shall be connected by clamps and the shaft with keyway shall be connected by keys.

Economic gantry type CNC cutting machine product parameters

型号Model | MCQC-2040 | MCQC-2060 | MCQC-2080 | MCQC-2560 | MCQC-3060 | MCQC-3080 | MCQC-30100 | MCQC-30120 |

有效切割宽度 | 2000 | 2000 | 2000 | 2500 | 3000 | 3000 | 3000 | 3000 |

有效切割长度 | 4000 | 6000 | 8000 | 6000 | 6000 | 8000 | 10000 | 12000 |

标配割炬数量 | 1 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

轨道长度 | 4、6、8、10、12…… 轨道:2米/节 ,可任意选配轨道长度 | |||||||

割炬行程 | 150 | |||||||

切割厚度 | 火焰切割 Flame cutting:5 - 200 mm 等离子切割 plasma cutting:1 - 50 mm | |||||||

切割速度 | 火焰切割 Flame cutting:0 - 1000 mm/min 等离子切割 plasma cutting:0 - 5000 mm/min | |||||||

空程速度 | 0 - 6000 mm/min | |||||||

输入电源 | AC220 V/ 380 V 50HZ | |||||||

驱动方式 | 双边驱动 Bilateral drive | |||||||

机床驱动电机功率 | 800 W/ 2500W | |||||||

切割方式 | 火焰切割:氧气+乙炔、丙烷 等离子切割:压缩空气、氧气、氮气等 | |||||||

The form is for reference only, please consult the staff for more information

Features of economical gantry type plasma CNC cutting machine

1. Beam: square pipe butt welding structure, with good rigidity, high precision, light weight, small inertia characteristics.

All welding parts are treated with vibration aging stress removal, which can effectively prevent the deformation of the structure.

2. Longitudinal and transverse drives: Precision pinion and rack (level 7 precision) is adopted for driving.

The vertical guide is made of the special precision steel rail, which ensures the smooth operation of the cutting machine, high precision, durability, clean and beautiful.

Planetary gear reducer is adopted to reduce speed, which can guarantee the precision and balance of motion perfectly.

3. Longitudinal drive frame (end frame) : horizontal guide wheels are installed at both ends, which can adjust the compacting degree of guide rail of eccentric wheel set at the bottom of the drive frame, so that the whole machine can keep stable guide during movement.

Equipped with a dust remover to sweep the debris accumulated on the surface of the guide rail at any time;

4. The driving system is a domestic step drive, according to the needs of users can choose the world's top products - imported Panasonic AC servo drive/domestic servo drive, so that the machine runs more smoothly, the speed range is wider, the acceleration time is shorter;

5. The lifting body adopts aluminum alloy structure, the lifting guide adopts linear guide, and the lifting adopts ball screw;

6. Easy to use automatic programming system, so that nc programming is no longer complex, easy;

7. The CNC control system adopts the self-developed control system, which has excellent stability and strong anti-interference ability in China.

Plasma cutting effect

Flame cutting effect