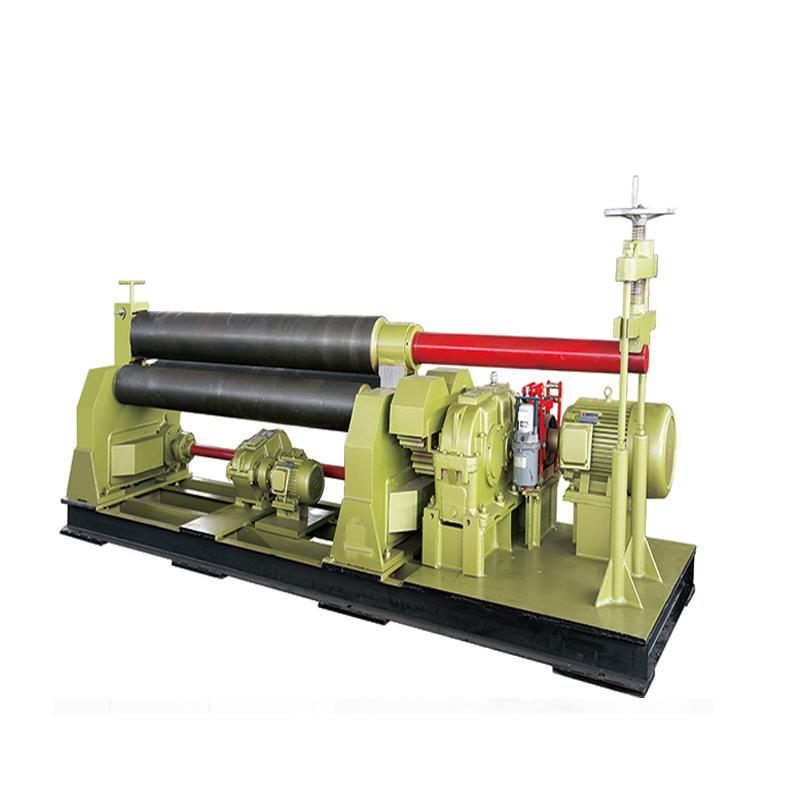

W11-Symmetric Three Rolling Machine

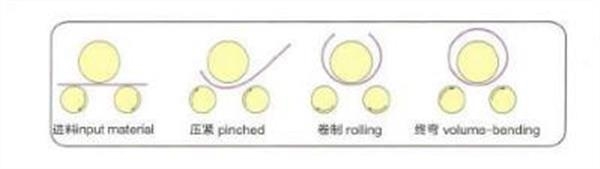

W11 symmetrical three-roller coiling machine is a mechanical symmetrical coiling machine, which works by the upper roller pressing down and the upper and lower roller matching.

The output shaft of the main reducer is driven to two lower rollers by a set of gears. The rotation direction of the roll shaft is changed by reversing the main motor.

One upper roller, two lower rollers, lifting screw, worm gear and some auxiliary parts.

The movement of the upper roll is achieved by moving up and down the lifting screw.

This type of winder is a typical mechanical winder, which is durable, solid, less investment, easy to operate, widely suitable for various working conditions and easy to maintain.

Used to roll plates into cylindrical, circular and conical shapes under normal temperature.Superior performance, compact structure, easy to operate.The upper roller lifting and tipping device adopts hydraulic drive.The main drive is transmitted by the motor through the triangular belt, and the reducer drives the two rollers, making the winding flexible.PLC programmable monitor is used for control, displacement sensor is used to detect the rise and fall of the upper roll, and digital display table is used for display.Improve product efficiency and product quality, the tipping frame adopts hydraulic tipping.

Compared with mechanical winder, this type of winder has high efficiency, but the disadvantage is that the remaining head of the winder needs to be rounded or prebent with other equipment.

W11- Series parameters of symmetrical plate winder

型号 | 最高弯曲厚度 | 最高弯曲宽度 | 弯曲速度 | 最小弯曲半径 | 钢板屈服极限 | 两下辊中心距 | 主电动机 |

W11-3*1250 | 3 | 1250 | 8.5 | 200 | 245 | 150 | 3 |

W11-6*1500 | 6 | 1500 | 5.5 | 350 | 245 | 210 | 5.5 |

W11-12*2500 | 12 | 2500 | 5.5 | 650 | 245 | 300 | 5.5 |

W11-16*2000 | 16 | 2000 | 5.5 | 700 | 245 | 300 | 15 |

W11-16*2500 | 16 | 2500 | 5.5 | 700 | 245 | 360 | 22 |

W11-25*2000 | 25 | 2000 | 5 | 1000 | 245 | 440 | 30 |

W11-25*2500 | 25 | 2500 | 4 | 1200 | 245 | 480 | 22 |

W11-20*2500 | 20 | 2500 | 5 | 850 | 245 | 440 | 30 |

W11-25*3000 | 25 | 3000 | 4 | 1200 | 245 | 550 | 30 |

W11-30*2500 | 30 | 2500 | 4.5 | 1100 | 245 | 550 | 37 |

W11-30*2000 | 30 | 2000 | 4 | 1200 | 245 | 480 | 22 |

W11-30*3000 | 30 | 3000 | 4 | 1200 | 245 | 600 | 30 |

W11-40*2500 | 40 | 2500 | 3.5 | 1400 | 245 | 600 | 37 |

W11-40*3000 | 40 | 3000 | 3.5 | 1600 | 245 | 600 | 45 |

W11-50*3000 | 50 | 300 | 3.5 | 2000 | 245 | 750 | 55 |

W11-60*3000 | 60 | 3000 | 3.5 | 2400 | 245 | 800 | 75 |

W11-70*3000 | 70 | 3000 | 3.5 | 2800 | 245 | 850 | 90 |

W11-80*3000 | 80 | 3000 | 3.5 | 3200 | 245 | 900 | 90 |

W11-90*3000 | 90 | 3000 | 3.5 | 3600 | 245 | 950 | 110 |

W11-100*3000 | 100 | 3000 | 3.5 | 4000 | 245 | 1000 | 110 |

W11-110*3000 | 110 | 3000 | 3.5 | 4400 | 245 | 1080 | 132 |

W11-120*3000 | 120 | 3000 | 3.5 | 4800 | 245 | 1160 | 132 |

The form is for reference only, please consult the staff for more information

Performance and characteristics of symmetrical three-roll plate rolling machine:

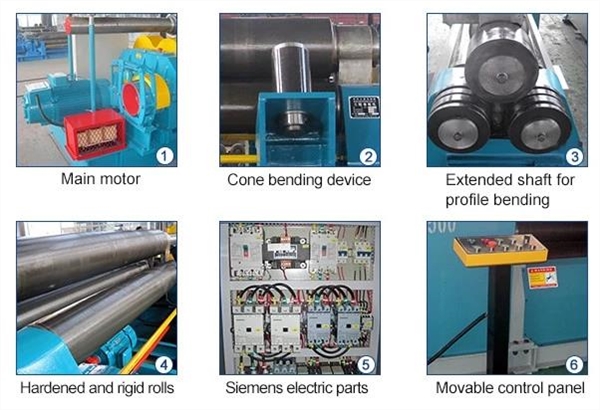

The structure of the machine is symmetrical with three rollers. The upper roller moves vertically at the symmetrical position of the center of the two lower rollers. It is obtained by acting the hydraulic oil in the hydraulic cylinder on the piston and is hydraulic transmission.

The two lower rollers rotate and engage with the lower roller gear through the output gear of the reduction gear to provide torque for the rolling plate.

The machine has compact structure and convenient operation and maintenance.

1) Simple, practical, economical and easy to operate;

2) The upper roller can be lifted mechanically or hydraulically;

3) It is necessary to use the remaining straight edge of pre-bending equipment;

4) Mobile electric cabinet and centralized control of electric appliances;

5) Install the mold at the end of the roller to roll profiles of different specifications;

6) Can bend conical workpiece