WE67K Series Electro-hydraulic Servo Press Brake CNC Bending Machine

WE67K Series Electro-hydraulic Servo Press Brake CNC Bending Machine adopts integral welding and integral processing structure. The main components of the body are analyzed with ANSYS finite element analysis software, which ensures the reliability and overall accuracy of the machine tool.

The main oil cylinder on both sides breaks through the stroke control mode of the traditional mechanical baffle type bending machine and adopts the closed-loop control mode consisting of the electro-hydraulic servo valve imported from Germany and the grating ruler imported from Germany.

The position feedback accuracy of the slider is high, the operation is accurate and stable, the synchronization performance is good, the bending accuracy and the repeated positioning accuracy of the slider are high;

All the functional parts in the rear baffle are imported to ensure the accuracy of the rear baffle, and according to customer requirements can adopt more complete functions of the rear baffle mechanism of the rear baffle;

The hydraulic system adopts the integrated control system imported from Germany, which reduces the installation of pipelines, ensures the working stability of the machine tool, and the appearance is simple and beautiful.

C-shaped plates are installed on both sides of the fuselage, and high-precision grating rulers are installed on the C-shaped plates, so as to avoid the influence of body deformation on the bending accuracy during bending.

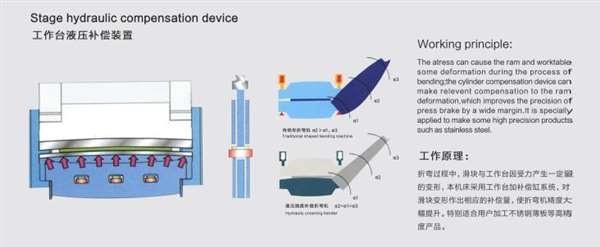

The lower table has hydraulic deflection automatic compensation mechanism, which can realize effective compensation without blind area, high bending precision and ensure long-term stability.

CNC system adopts the ESA in Italy, the Netherlands or Switzerland CYBELEC DELEM company of electro-hydraulic servo bending machine, CNC system can realize graphics programming, Angle correction compensation bending Angle, bending stress calculation and automatic adjusting automatically, automatic calculation table spread length deformation compensation amount, workpiece, bottom bending pressure, opening distance behind, escaping, and other functions.

WE67K series electro-hydraulic servo CNC bending machine model

型号 | 公称压力 | 工作台长度 | 立柱间距 | 喉口深度 | 滑块行程 | 最大开启高度 | 主电机功率 | 外形尺寸 |

(KN) | (mm) | (mm) | (mm) | (mm) | (mm) | (KW) | (mm) | |

WE67K-40t/2200 | 400 | 2200 | 1775 | 250 | 175 | 320 | 5.5 | 2300×1500×2000 |

WE67K-40t/2500 | 400 | 2500 | 1975 | 250 | 175 | 320 | 5.5 | 2600×1500×2000 |

WE67K-63t/2500 | 630 | 2500 | 2095 | 250 | 175 | 360 | 5.5 | 2600×1600×2300 |

WE67K-63t/3200 | 630 | 3200 | 2570 | 250 | 175 | 360 | 5.5 | 3300×1600×2300 |

WE67K-80t/3200 | 800 | 3200 | 2565 | 320 | 175 | 360 | 7.5 | 3300×1700×2300 |

WE67K-80t/4000 | 800 | 4000 | 3165 | 320 | 175 | 360 | 7.5 | 4100×1700×2300 |

WE67K-100t/3200 | 1000 | 3200 | 2560 | 320 | 215 | 360 | 7.5 | 3300×1800×2400 |

WE67K-100t/4000 | 1000 | 4000 | 3165 | 320 | 215 | 360 | 7.5 | 4100×1800×2500 |

WE67K-125t/3200 | 1250 | 3200 | 2550 | 320 | 215 | 360 | 7.5 | 3250×1920×2450 |

WE67K-125t/4000 | 1250 | 4000 | 3450 | 320 | 215 | 360 | 7.5 | 4100×1920×2500 |

WE67K-160t/3200 | 1600 | 3200 | 2540 | 320 | 215 | 440 | 11 | 3300×1600×2600 |

WE67K-160t/4000 | 1600 | 4000 | 3140 | 320 | 215 | 440 | 11 | 4100×2000×2600 |

WE67K-160t/6000 | 1600 | 6000 | 4740 | 320 | 215 | 440 | 11 | 6100×2000×2600 |

WE67K-200t/3200 | 2000 | 3200 | 2540 | 320 | 215 | 530 | 11 | 3300×2100×2800 |

WE67K-200t/4000 | 2000 | 4000 | 3140 | 320 | 215 | 530 | 15 | 4100×2100×2900 |

WE67K-200t/5000 | 2500 | 5000 | 3120 | 400 | 215 | 530 | 15 | 5100×2100×3000 |

WE67K-250t/4000 | 2500 | 4000 | 3120 | 400 | 215 | 560 | 18.5 | 4100×2200×3500 |

WE67K-250t/5000 | 2500 | 5000 | 3920 | 400 | 215 | 560 | 18.5 | 5100×2200×3500 |

WE67K-250t/6000 | 2500 | 6000 | 4720 | 400 | 250 | 560 | 18.5 | 6100×2200×3500 |

WE67K-300t/5000 | 3000 | 5000 | 39100 | 400 | 250 | 560 | 22 | 5100×2600×4000 |

WE67K-300t/6000 | 3000 | 6000 | 4710 | 400 | 250 | 560 | 22 | 6100×2600×4000 |

WE67K-300t/7000 | 3000 | 7000 | 5620 | 400 | 250 | 560 | 22 | 7100×2600×4400 |

WE67K-350t/6000 | 3500 | 6000 | 5100 | 400 | 250 | 560 | 30 | 6100×2600×4200 |

WE67K-350t/7000 | 3500 | 7000 | 5620 | 400 | 250 | 560 | 30 | 7100×2600×4500 |

WE67K-400t/4000 | 4000 | 4000 | 3100 | 400 | 300 | 620 | 30 | 4100×2700×3800 |

WE67K-400t/6000 | 4000 | 6000 | 4280 | 400 | 320 | 630 | 30 | 6100×2800×4200 |

WE67K-500t/5000 | 5000 | 5000 | 4100 | 400 | 320 | 630 | 37 | 5100×3000×4400 |

WE67K-500t/6000 | 5000 | 6000 | 4820 | 400 | 320 | 630 | 37 | 6100×3000×4700 |

WE67K-500t/7000 | 5000 | 7000 | 5620 | 400 | 320 | 630 | 37 | 7100×3000×4900 |

WE67K-600t/6000 | 6000 | 6000 | 4820 | 400 | 320 | 630 | 45 | 6100×2965×4700 |

WE67K-600t/7000 | 6000 | 7000 | 5620 | 400 | 320 | 630 | 55 | 7100×2965×4900 |

The form is for reference only, please consult the staff for more information

This machine is equipped with hydraulic electric control, freely adjustable slider travel, and slow, semi-automatic, automatic operation standard module test and adjustment easy.

Curved design, double cylinder working at the same time, balanced operation, convenient and safe. Maintain pressure and delay time as a function of low dead spots to ensure the accuracy of work. Under the condition of national standards, the accuracy of bending angles can reach ±45 %. The function drops slowly and the operator can control the work better.