How to operate the shearing machine safely? Mingcheng Machinery Equipment

Release Time : 2020-09-17 View Count : 次1 cut

1.1 Check whether the material and thickness of the sheet are correct in the figure, whether the surface of the sheet has unevenness, defects, pay attention to the direction of the texture, and determine the cutting sequence.

1.2 Adjust the gap between the upper and lower cutters according to the thickness of the plate, adjust the position of the back gauge, whether the cut material is accurate, and whether the width at both ends is consistent.

1.3 During the cutting operation, always check whether the size of the cut sheet (length, width, diagonal) conforms to the drawing.

1.4 The cut sheets should be sorted and stacked, neatly stacked, and marked with name and size to protect the surface of the board from damage.

1.5 When shearing small pieces of sheet material, it must be cut after the pressure column of the shearing machine can be cut back, and pay attention to the safe operation.

2 How to use the shears

2.1 After starting the shearing machine, make a number of cycles of idling to ensure that sheets of different thickness (T≤6mm) are tested under normal conditions and familiar with the performance of the shearing machine.

2.2 The blade gap must be adjusted before trial cutting. If the corresponding blade gap is not adjusted, the durability of the blade will be affected.

2.3 Open the pressure gauge to observe the oil pressure during the shearing process. The pressure should be less than 1.5Mpa when cutting 1.0mm stainless steel plates. It is not allowed to cut sheets with a thickness greater than 6mm illegally to avoid damage to the machine tool!

3 Operating procedures

3.1 The operator must be familiar with the general structure and performance of the equipment, and it is strictly prohibited to use the equipment with super performance.

3.2 Before starting the equipment, add oil according to the equipment lubrication regulations and check the oil volume of the oil cylinder.

3.3 The upper and lower blades should be adjusted before work. The blade gap is determined according to the thickness of the sheared steel plate. Generally, it is between 8-10% of the thickness of the plate to be cut. Each gap adjustment should be locked and adjusted according to the thickness of each plate. (The adjustment comparison table refers to the clearance adjustment comparison on the machine tool)

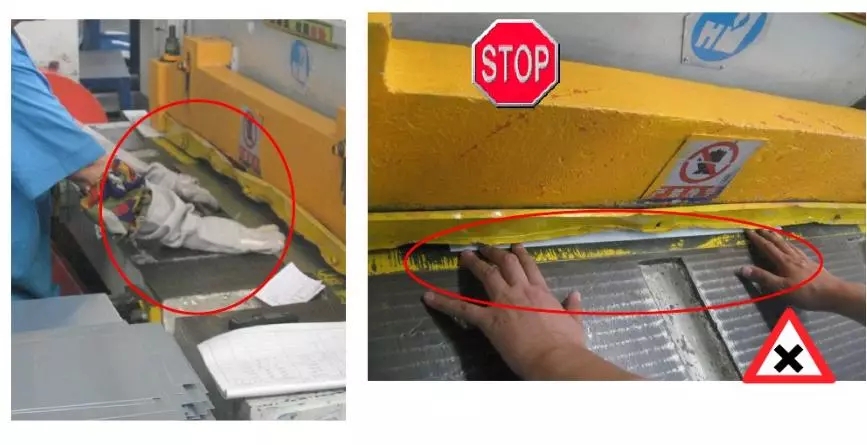

3.4 It is strictly forbidden to wipe the machine tool during the work, and no debris or tools are allowed to be placed on the workbench to prevent the blade from being damaged by the cutting edge. When cutting the material, the pressing plate must be pressed tightly to prevent the material from rebounding and hurting people.

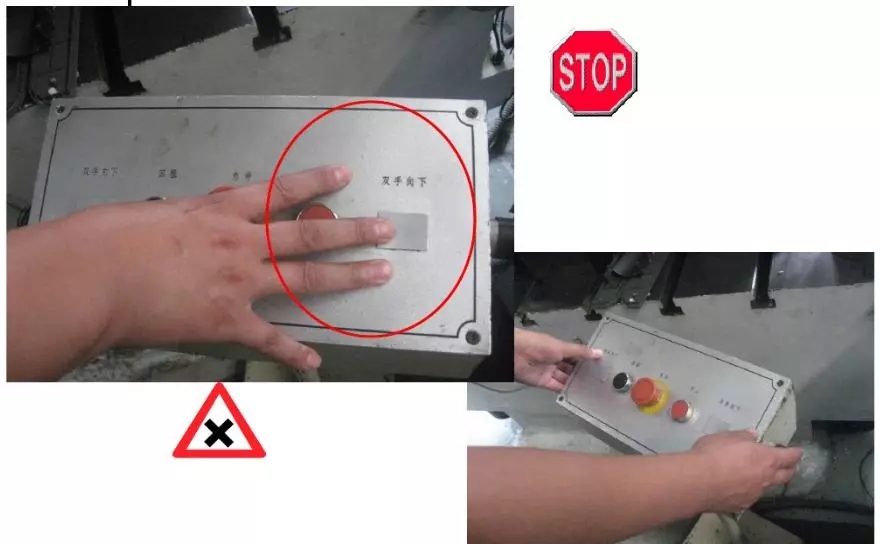

3.5 Always pay attention to whether the locking mechanism, clutch, brake, and foot switch are abnormal or malfunctioning. When cutting, you should concentrate on cutting. If the equipment is abnormal, stop cutting immediately, cut off the power supply and notify the maintenance personnel for maintenance.

3.6 In accordance with relevant regulations, pay attention to safe and civilized production, and the surrounding environmental sanitation.